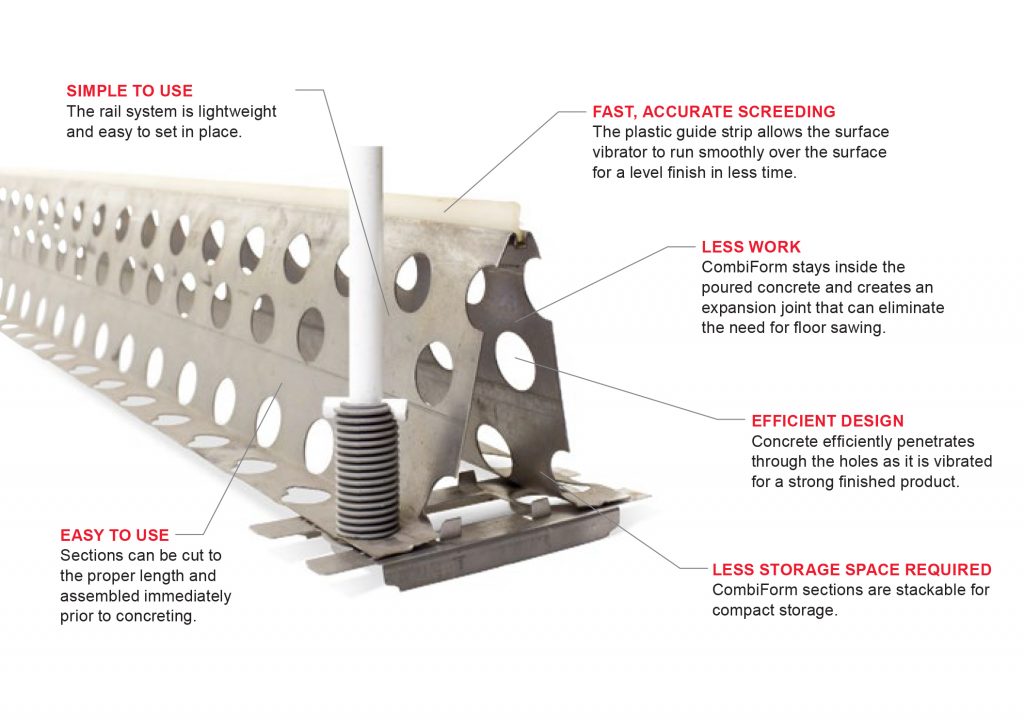

CombiForm is a leave-in-place screed rail system to guide beams and screeds.

CombiForm ensures an instant levelled floor with no need for further excessive grinding. The low-weight but robust components allow for crack control ideal for new and refurbished floors. The systems provides the opportunity to create slopes and the floor can be designed directly without further layers of concrete/plastic.

Discover the benefits of casting concrete floors quicker and more efficiently to minimise work, time and cost. That is why the CombiForm Screed Rail System is an excellent choice. CombiForm will help you to level the floor more easily and accurately, giving a smoother and more durable floor!

With low production costs, quick assembly and timesaving capabilities CombiForm is ideal for most concrete flooring projects.

CombiForm, with it’s time-saving and low cost implementation makes it ideal for the following:

Flooring specialists – Save time on projects with CombiForm’s accuracy

Major construction companies – Bespoke large scale concrete flooring solutions

Designers/Architects – CombiForm allows greater precision and planning with pre-assembly

Contractors – The lightweight CombiForm product allows for a one person job

CombiForm Benefits

Total time saving

No need for waiting to even up the floor

No need of excessive grinding after curing

No need of saw cuts

Minimum need of extra plastic layers

Quick

Assembled immediately prior to concrete pour

Instant pouring

Light weight – one person operation

Floor levelled and flat for instant next step of flooring

Low production costs

Minimum need of plastic filler

More accurate calculation for required concrete

Minimum need of corrective after work

Less labour work required

Quality

Strong joints – construction and/or contraction joints

Crack allocation control instantly while curing

- CombiForm can be set out by most contractors

Minimum risk of warranty issues for years to come

APPLICATIONS: Directly on sub-base

*The Screed rails are supported and levelled on either concrete pads or the combination of locking clips, adjustment screws and ground plates. The latter solution allows levelling throughout the entire casting. The distance between supports is recommended in most cases to be 1100 mm centres. The section width will vary depending on the size of the vibration bridge. Dowel bars can be placed with 250 mm centres, or follow the floor specifications. It is very important that the ground is correctly prepared prior to the pour. The plastic strip will in most cases be left in the floor and it works as a crack allocation guide.

APPLICATIONS: Insulated ground

The height of the Screed rail is selected depending on the depth of the slab and the size of the aggregates, see technical manual.

The height of the Screed rail is selected depending on the depth of the slab and the size of the aggregates, see technical manual.*

Screed rails are supported and levelled on a combination of locking clips, adjustment screws and ground plates. The distance between supports is recommended in most cases to be 1100 mm centres. Dowel bars can be placed with 250 mm centres, or follow the floor specifications. The plastic strip will in most cases be left in the floor and it works as a crack allocation guide.

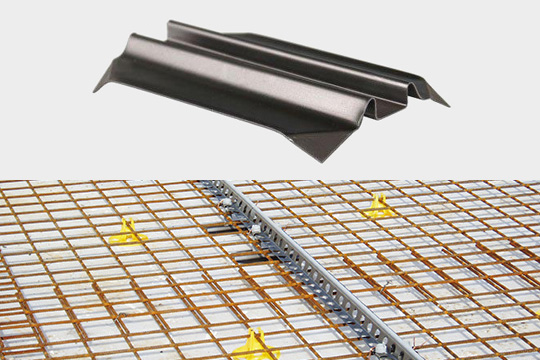

APPLICATIONS: Rough Cast Slab, Pre-Fabricated Floor Sections

The height of the Screed rail is selected depending on the depth of the slab and the size of the aggregates, see technical manual.

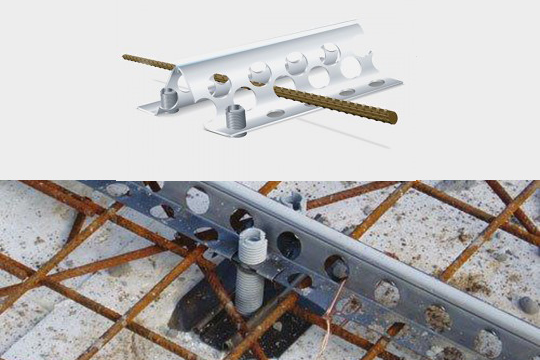

*To get the Screed rails to stay in place, there are several methods, two of them are:

- Use concrete nails or screws and punch them through the adjustment screws into the ground. This method allows levelling of the Screed rails.

- Anchor the reinforcement bars/mesh onto the ground and secure the Screed rail onto the reinforcement bars/mesh with steel wires, or similar.

Section distances between the Screed rails are recommended to 2000 – 2500 mm centres, or follow the floor specifications. It is very important that the ground is correctly prepared prior to the pour. The plastic strip will in most cases be left in the floor and it works as a crack allocation guide.

CombiForm profiles

CombiForm technical information, suitable for most concrete floors:

C25 (25mm) – To make new concrete surface layer on top of an old, metal decking etc..

C45 (45mm) – Standard floors

C65 – C125 (65-125mm) – Standard housing applications, industrial floors etc..

C145 (145mm) – Industrial floors, heavy duty floors.

COMPONENTS: Screed Rails

Screed rails are the main components. The Screed rails combine stability, accuracy and light weight which assures quality casting.

The Screed rails are available in seven different heights which will fit slabs from metal decking to heavy duty industrial floors.

The Screed rails are stackable and easy to handle; it is a one-man operation to assemble. The Screed rails can be levelled with adjustment screws or directly on concrete pads. The Screed rails give a true construction joint as well as a controlled crack propagation.

COMPONENTS: Locking Clips

Locking clips will secure the triangular profile of the Screed rails to create a rigid support and form work.

The clips are easy to mount and can be placed anywhere along the Screed rail. Recommended distance is 1000 – 1100 mm centers.

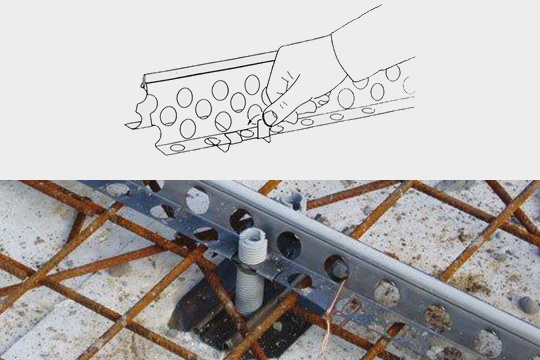

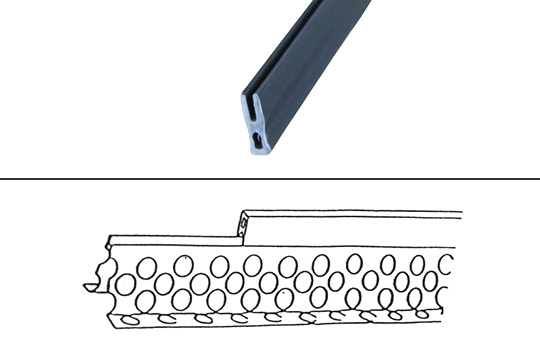

COMPONENTS: Top Extender

The Top Extender is easily mounted directly on top of the Screed rail. It allows for increased concrete cover and acts as a saw cut. It can be left in or taken out if different joint filler is required. Cost and time saving. Recommended for;

- Any floor where increased cover is required

- Any heavy duty floor – internally or externally

- Chemical and aggressive environments

The Top Extender can also be delivered in different colors for a modern designed concrete floor or marking out different bays.

COMPONENTS: Adjustment Screws

The adjustment screws allow for an easy, accurate and stable levelling of the Screed rail. The floor height can be set with great precision, for sloping as well as for super flat concrete floors. The screws are provided in two heights, 60 and 90 mm which cover most of the common slab depths.

COMPONENTS: Ground Plate

The ground plate is used in conjunction with the adjustment screws. The design of the ground plate gives stable support with minimum risk of slip.

The plates are recommended to be used on every surface except those that should not be penetrated such as vapor protected slabs.

Ready to contact us?

DO YOU HAVE A BIG PROJECT WE CAN HELP WITH?